-

Today's HoursClosed

-

Monday 8:00AM - 5:00PM Tuesday 8:00AM - 5:00PM Wednesday 8:00AM - 5:00PM Thursday 8:00AM - 5:00PM Friday 8:00AM - 5:00PM Saturday Closed Sunday Closed

-

Inventory

Avonlea has a wide selection of new and used equipment

Summers Supercoulter

|

First introduced in 1999, the Supercoulter is the original vertical tillage tool. In fact, it’s still one of the few true vertical tillage tools on the market today. That’s because, while other manufacturers may claim to offer vertical tillage, their equipment usually has concave, angled blades that move soil laterally. This can cause compacted soil layers, defeating the entire purpose of vertical tillage. On the other hand, Summers uses two rows of straight-tracking coulter blades on the Supercoulter to aggressively chop residue and slice through the soil, eliminating soil layers and promoting deep root growth. Applications: vertical tillage, spring tillage, spring residue management, fall tillage, fall residue management, soil conditioning, seedbed preparation, no till, conventional tillage |

| SC1510 (11'-15') | ||

| Working Width | 11’ | 15’ |

| Transport Width | 11' 1" | 15' 1" |

| Transport Height | 5' 8" | 5' 8" |

| Length Without Attachments | 20’ | 20’ |

| Gangs | 4 | 4 |

| Total Blades | 26 | 36 |

| Blade Spacing | 10" | 10" |

| Total Bearings | 8 | 8 |

| Gang Mounting | 2 C-shanks per gang section | 2 C-shanks per gang section |

| Wheels, Center | 2 sets, duals | |

| Hubs, Center | 6-bolt, HD* | 6-bolt, HD* |

| Tires, Center | IF280/70R15 ** | IF280/70R15 ** |

| Hyd. Cyl., Main Lift | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels |

| Master Hyd. Cyl. Dia. | 4.5" | 4.5" |

| Estimated Weight*** | 6,970 lbs. | 8,850 lbs. |

| Approx. Engine HP*** | 55-95 | 74-129 |

| * 8-bolt HD optional ** IF320/70R15 optional *** Weight and HP requirements without mounted attachments | ||

| SC1030 (20'-30') | SC1535 (30' HD) | |||

|---|---|---|---|---|

| Working Width | 20’ | 23’ | 30’ | 30’ |

| Transport Width | 14' 3" | 15' 8" | 15' 4" | 19' 6" |

| Transport Height | 8' 8" | 10' 3" | 14' | 10' 9" |

| Length Without Attachments | 20’ | 20’ | 20’ | 20' |

| Gangs | 8 | 8 | 12 | 8 |

| Blades, Center | 26 | 26 | 26 | 36 |

| Blades Per Wing | 11 | 15 | 18 | 18 |

| Total Blades | 48 | 56 | 72 | 72 |

| Blade Spacing | 10" | 10" | 10" | 10" |

| Total Bearings | 16 | 16 | 24 | 16 |

| Gang Mounting | 2 C-shanks per gang section | 2 C-shanks per gang section | 2 C-shanks per gang section | 2 C-shanks per gang section |

| Wheels, Center | 2 sets, duals | 2 sets, duals | 2 sets, duals | 2 sets, duals |

| Wheels, Wing | N/A | 1 set, duals | 1 set, duals | 1 set, duals |

| Hubs, Center | 8-bolt, HD | 6-bolt, HD* | 8-bolt, HD | 8-bolt, HD |

| Hubs, Wing | N/A | 6-bolt, HD* | 6-bolt, HD* | 6-bolt, HD* |

| Tires, Center | IF320/70R15*** | IF280/70R15** | IF320/70R15*** | IF320/70R15*** |

| Tires, Wing | N/A | IF280/70R15 | IF280/70R15 | IF280/70R15** |

| Hyd. Cyl., Main Lift | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels |

| Master Hyd. Cyl. Dia. | 4.5" | 5" | 5" | 5.5" |

| Hyd. Cyl., Wing Lift | 4" x 33" | 4" x 33" | 5" x 33" | 4" x 33" |

| Estimated Weight*** | 13,550 lbs. | 15,100 lbs. | 17,950 lbs. | 21,350 lbs. |

| Approx. Engine HP*** | 100-172 | 112-197 | 147-257 | 147-270 |

| * 8-bolt HD optional ** IF320/70R15 optional *** 340/65R18 optional **** Weight and HP requirements without mounted attachments |

* 8-bolt HD optional ** IF320/70R15 optional *** 340/65R18 optional **** Weight and HP requirements without mounted attachments | |||

| SC1530 (30'-40') | |||

|---|---|---|---|

| Working Width | 30’ | 35’ | 40’ |

| Transport Width | 19' 6" | 19' 6" | 19' 6" |

| Transport Height | 10' 9" | 13- 10" | 16' |

| Length Without Attachments | 20' | 20' | 20' |

| Gangs | 8 | 12 | 12 |

| Blades, Center | 36 | 36 | 36 |

| Blades Per Wing | 18 | 24 | 30 |

| Total Blades | 72 | 84 | 96 |

| Blade Spacing | 10" | 10" | 10" |

| Total Bearings | 16 | 24 | 24 |

| Gang Mounting | 2 C-shanks per gang section | 2 C-shanks per gang section | 2 C-shanks per gang section |

| Wheels, Center | 2 sets, duals | 2 sets, duals | 2 sets, duals |

| Wheels, Wing | 1 set, duals | 1 set, duals | 1 set, duals |

| Hubs, Center | 6-bolt, HD* | 8-bolt, HD | 8-bolt, XHD |

| Hubs, Wing | 6-bolt, HD* | 6-bolt, HD* | 8-bolt, HD |

| Tires, Center | IF280/70R15 ** | IF320/70R15*** | 340/65R18 |

| Tires, Wing | IF280/70R15 ** | IF280/70R15 ** | IF320/70R15*** |

| Hyd. Cyl., Main Lift | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels |

| Master Hyd. Cyl. Dia. | 5" | 5.5" | 5.5" |

| Hyd. Cyl., Wing Lift | 4" x 33" | 5" x 33" | 5" x 33" |

| Estimated Weight*** | 17,400 lbs. | 20,500 lbs. | 22,200 lbs. |

| Approx. Engine HP*** | 147-257 | 175-301 | 240-420 |

| * 8-bolt HD optional ** IF320/70R15 optional *** 320/65R18 optional **** Weight and HP requirements without mounted attachments | |||

| SC1550 (45'-50') | ||

|---|---|---|

| Working Width | 45’ | 50’ |

| Transport Width | 19' 6" | 19' 6" |

| Transport Height | 14' 4" | 16' 8" |

| Length Without Attachments | 20' | 23" |

| Gangs | 16 | 16 |

| Blades, Center | 36 | 36 |

| Blades Per Wing | 24+12 | 30+12 |

| Total Blades | 108 | 120 |

| Blade Spacing | 10" | 10" |

| Total Bearings | 32 | 32 |

| Gang Mounting | 2 C-shanks per gang section | 2 C-shanks per gang section |

| Wheels, Center | 2 sets, duals | 2 sets, duals |

| Wheels, Wing | N/A | 1 set, duals |

| Hubs, Center | 8-bolt, XHD | 8-bolt, XHD |

| Hubs, Wing | 8-bolt, HD | 8-bolt, XHD |

| Tires, Center | 340/65R18 | 340/65R18 |

| Tires, Wing | IF280/70R15 * | 320/65R18 |

| Hyd. Cyl., Main Lift | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels |

| Master Hyd. Cyl. Dia. | 6" | 6" |

| Hyd. Cyl., Wing Lift | 5" x 33" | 5" x 33" |

| Estimated Weight*** | 26,100 lbs. | 27,250 lbs. |

| Approx. Engine HP*** | 240-420 | 250-450 |

| * IF320/70R15 optional ** Weight and HP requirements without mounted attachments | ||

| SC1535 (40' HD) | SC1556 (60') | |

| Working Width | 40’ HD | 60’ |

| Transport Width | 19' 6" | 22' 10" |

| Transport Height | 16' | 17' 4" |

| Length Without Attachments | 20' | 26' |

| Gangs | 12 | 20 |

| Blades, Center | 36 | 36 |

| Blades Per Wing | 30 | 30+24 |

| Total Blades | 96 | 144 |

| Blade Spacing | 10" | 10" |

| Total Bearings | 24 | 40 |

| Gang Mounting | 2 C-shanks per gang section | 2 C-shanks per gang section |

| Hubs, Center | 8-bolt, XHD | 10-bolt, XHD |

| Hubs, Wing | 8-bolt, HD | 8-bolt HD |

| Tires, Center | 340/65R18 | 425/65R22.5 |

| Tires, Wing | 12.5L x 15" | IF320/70R15 |

| Hyd. Cyl., Main Lift | One rephasing 8" stroke per set of wheels | One rephasing 8" stroke per set of wheels |

| Master Hyd. Cyl. Dia. | 6" | 6" |

| Estimated Weight** | 25,374 lbs. | 33,850 lbs. |

| Approx. Engine HP** | 218-385 | 342-620 |

| ** Weight and HP requirements without mounted attachments | * 8-bolt HD optional ** IF320/70R15 optional *** Weight and HP requirements without mounted attachments |

|

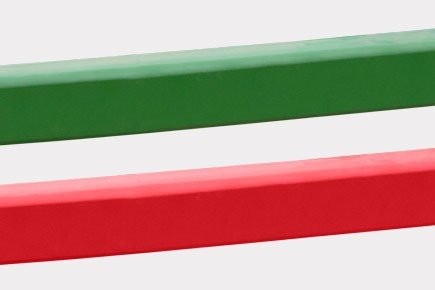

Green or Red – You ChooseBrand loyalty is fierce between Team Red and Team Green in the agriculture world, which is something Summers has long understood. Well, we’ve listened and are offering you a choice. Now any time you order custom equipment from Summers, pick between the color that fits your operation best – green or red. It’s that simple. |

|

Mounted on a rectangular tube frame, the Supercoulter’s blades are designed to run straight for true vertical tillage performance. Simply put, it doesn’t move soil horizontally. Instead, it “scores” the soil, helping to achieve optimal soil fracturing and promoting deep root growth. |

|

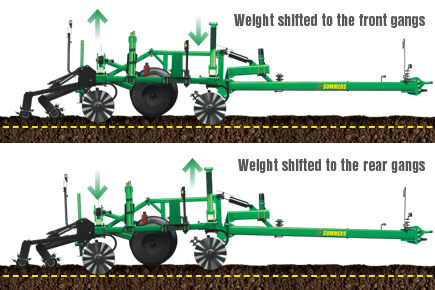

The patented hydraulic hitch allows you to transfer weight between the front and rear gangs. Placing more weight on the front helps the Supercoulter slice through tough residue and hard, dry ground. Shifting weight to the rear results in more aggressive soil movement and better residue incorporation. The hydraulic hitch can also be operated in float position, which works well for seedbed preparation and operation in rocky conditions. |

|

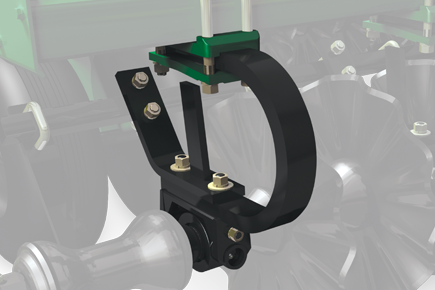

The unique Super-Flex™ gang mounting system is designed to absorb shocks from rocks and stumps, providing protection from blade damage. The toggle-mounted, triple-seal ball bearings are also designed to self-align as the gang flexes. |

|

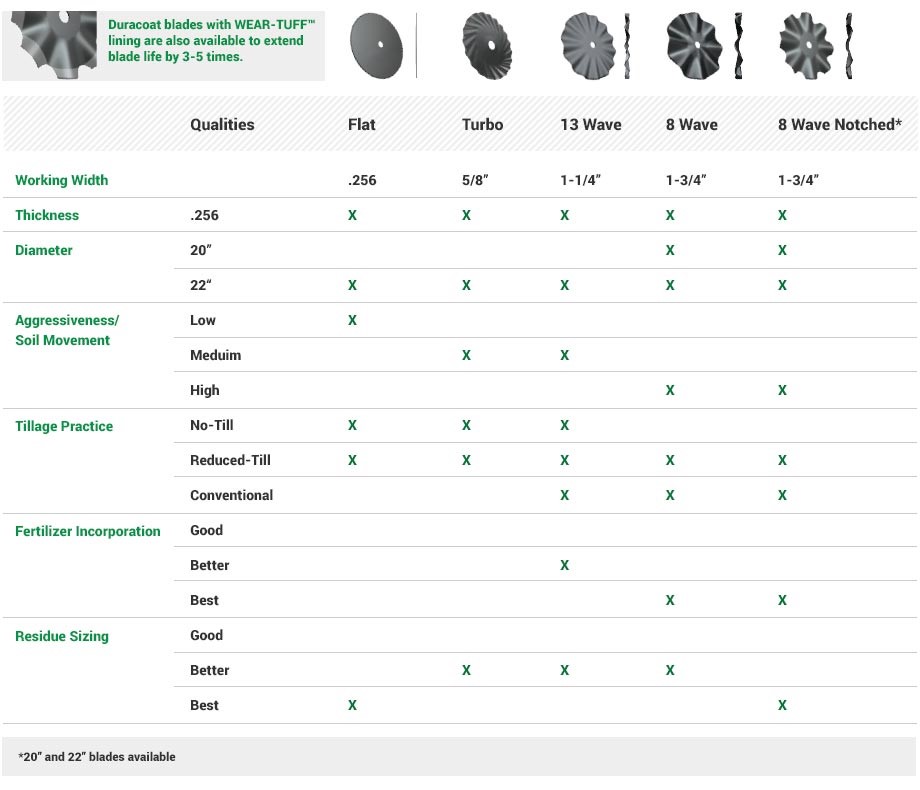

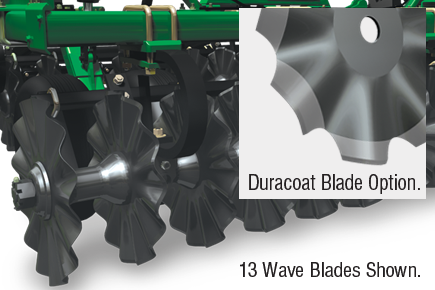

The Supercoulter is offered with a variety of blade options to customize your tillage performance. The front and rear gangs can even be equipped with different blade types to match any personal preference. Duracoat blades with WEAR-TUFF™ lining are also available to extend blade life by as much as 3 to 5 times. |

|

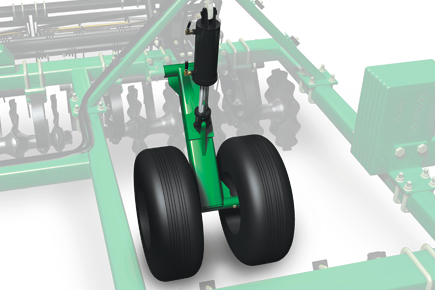

Dual axles help the Supercoulter maintain an accurate depth along all field contours. Also, the standard high-floatation tires and heavy-duty hubs are ideal for use in a variety of soil conditions. |

|

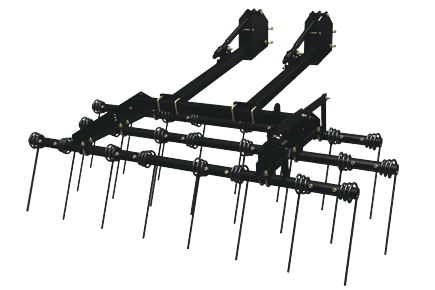

Optional 3- and 4-bar harrows can be adjusted for deep or shallow penetration. They feature a heavy, yet flexible design for floating over rocks and deep ditches. |

|

For optimum residue sizing and incorporation, rolling choppers are an ideal attachment. They come with induction-hardened replaceable blades and triple-lip-sealed bearings for maximum durability. |

|

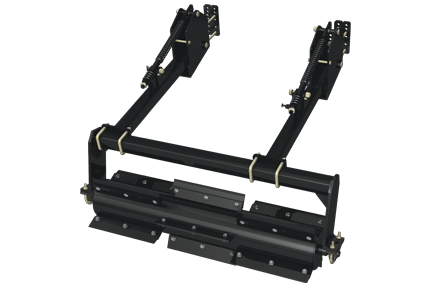

Featuring patent-pending internal mud scrapers, the rolling baskets are ideal for breaking up clumps and providing a uniform soil profile in most conditions. They are used in conjunction with MH1104 mounted harrows for the ultimate field finishing tool. |

True Vertical Tillage

True Vertical Tillage Hydraulic Hitch

Hydraulic Hitch Super-Flex™ C-Shanks

Super-Flex™ C-Shanks Blades

Blades Accurate Depth Control

Accurate Depth Control Mounted Harrows

Mounted Harrows Mounted Rolling Choppers

Mounted Rolling Choppers Mounted Harrow/Basket Combo

Mounted Harrow/Basket Combo