Aeration/Cooling Grain

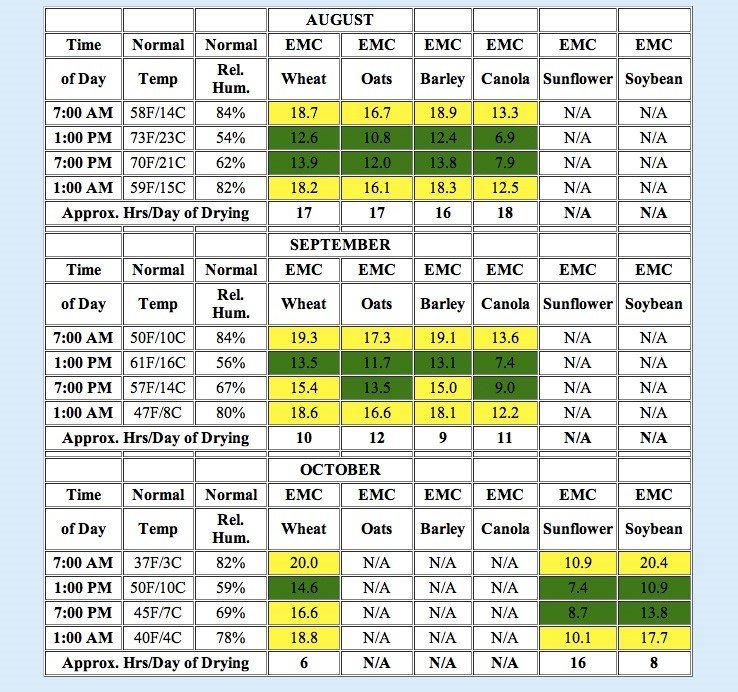

The objective of grain storage management is to prevent the grain from spoiling in the bin. As you can see from looking at the Wheat Storage Time Chart, you can increase the safe storage time by cooling and/or drying the grain.

Even when a crop is harvested dry, it is important to cool the bin. Grain will go through a sweat process after being harvested and it is critical to remove the heat and moisture from the bin. The larger the bins are, the more critical proper aeration becomes.

THE SWEAT PROCESS:

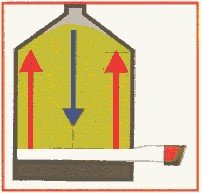

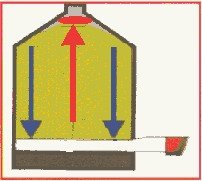

In the fall as the weather cools down, the grain against the walls of the bin cools first. Cool air will then move downward inside the bin and settle along the floor. The cool air displaces the warm air at the center of the bin and forces it upwards. This warm moist air then collects at the top of the bin and will often form a crust where mold and insects thrive.

In the spring the opposite occurs and spoilage occurs along the floor. To prevent the spring and fall sweat cycles from damaging your grain Avonlea recommends that you keep your grain within 10 degrees F of the outside air temperature. A low volume aeration fan will do this job for you. A higher volume aeration fan will also do the same job more quickly. Avonlea recommends that you monitor what is happening in your bins with temperature cables. This will eliminate the guesswork and the power saved could easily pay for the cables.

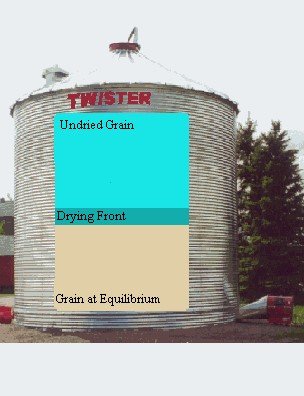

When you turn on your aeration fan, air is introduced into the bottom of the grain bin. This air will absorb moisture from grain at the bottom until equilibrium is reached for that Temp/RH. Once the grain has reached equilibrium with the air no more drying will occur in that area. The air will then move through the grain at the bottom of the bin and begin drying the grain above it. The bin dries from the bottom up and no drying will occur at the top of the bin until the grain at the bottom is at equilibrium. By using a temperature cable it is possible to follow this drying process in the bin:

After the fan is turned on the whole bin will go to the same temperature if the moisture content is the same.

As the grain reaches equilibrium at the bottom of the bin the temperature will be slightly higher in this area. The reason for this is that evaporation of moisture (cooling effect) has ceased.

Above the dry layer in the bin will be a wetter layer of grain. This area is called the drying front. The temperature in this region will be cooler than any other spot in the bin. This is because the greatest amount of evaporation (cooling effect) takes place here.

Above the drying front will be the grain not yet dried. The temperature of this grain will be warmer than the drying front but cooler that the dry grain.

NOTE: It is recommended that you do NOT stop the aeration fan until the bin is dry. It is possible that the drying front could stall in the bin and spoilage could occur.

Below is a chart listing normal temperatures/relative humidities for Manitoba: