Summers Mounted Harrow

|

Summers harrows are the toughest in the industry. They offer unmatched performance for distributing residue and leveling the soil in some of the most challenging conditions. Available in 3-bar and 4-bar configurations, the harrows are compatible with a wide variety of implements from Summers, as well as tillage tools from other manufacturers.

|

| MH1094 (3/8" x 18.5" tines) | MH1104 (1/2" x 20" tines) | MH1105 (1/2" x 26" tines) | MH1106 (9/16" x 26" tines) | MH1108 (5/8" x 28" tines) | |||||||||||

| Width | 4' 6" | 6' | 7' 6" | 6' | 8' | 10' | 6' | 8' | 10' | 6' | 8' | 10' | 6' | 8' | 10' |

| Tine Diameter | 3/8" | 3/8" | 3/8" | 1/2" | 1/2" | 1/2" | 1/2" | 1/2" | 1/2" | 9/16" | 9/16" | 9/16" | 5/8" | 5/8" | 5/8" |

| Tine Length | 18.5" | 18.5" | 18.5" | 20" | 20" | 20" | 26" | 26" | 26" | 26" | 26" | 26" | 28" | 28" | 28" |

| # of Tines Per Bar | 3 | 4 | 5 | 3 | 4 | 5 | 3 | 4 | 5 | 3 | 4 | 5 | 3 | 4 | 5 |

| Mounting Bar Diameter | 2" | 2" | 2" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" | 2-3/8" |

| Weight (3-Bar)* | 120 lbs. | 152 lbs. | 186 lbs. | 210 lbs. | 260 lbs. | 319 lbs. | 215 lbs. | 266 lbs. | 326 lbs. | 230 lbs. | 290 lbs. | 354 lbs. | 255 lbs. | 320 lbs. | 391 lbs. |

| Weight (4-Bar)* | 150 lbs. | 190 lbs. | 232 lbs. | 290 lbs. | 352 lbs. | 426 lbs. | 296 lbs. | 359 lbs. | 434 lbs. | 314 lbs. | 382 lbs. | 472 lbs. | 344 lbs. | 424 lbs. | 516 lbs. |

| Usage | Level and firm a variety of soil conditions; distribute residue | Low frame implements | Lateral action and smoother field finish | Aggressive leveling and maximum residue flow | Most extreme conditions | ||||||||||

| * Section only | * Section only | * Section only | * Section only | * Section only | |||||||||||

|

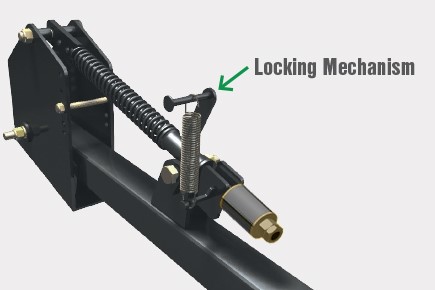

To match any field condition, the tine angle can easily be changed to one of five positions. The rear-mounted lever simply locks into place for quick adjustment, and the front bar is independently adjustable. |

|

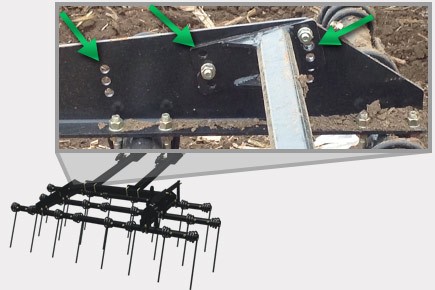

The front row of harrow tines can be adjusted to be less or more aggressive than the other rows. Three holes (indicated by arrows in the photo) allow the user to make these fine-tune adjustments to fit the desired finish of their field. |

|

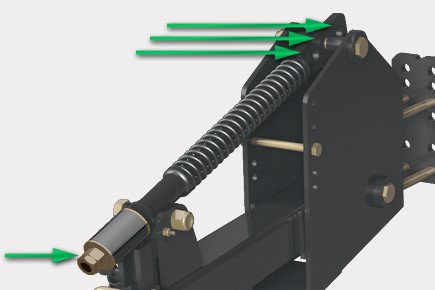

The mounted harrow arm can be raised or lowered for the optimal height on any piece of tillage equipment. Three holes at the top of the spring rod allow for set height settings, while a nut at the bottom end of the spring rod offers incremental adjustments to fine-tune the fit. |

|

The free-floating tines are equipped with 1/2-inch stop bolts. |

|

Once the height of the harrow is set, the sections can be “tipped” to make level. This is accomplished by adjusting the crossbar within the harrow section. There are two ways to mount the harrow in order to change distance from the machine. Each position has a series of holes that allows the harrow to tilt relative to the arm. |

|

Get the benefits of harrow attachments no matter what tillage equipment you run. Whether it’s a big ag company or smaller one-off, Summers mounted harrows can attach to almost any piece of tillage equipment, regardless of manufacturer. |

|

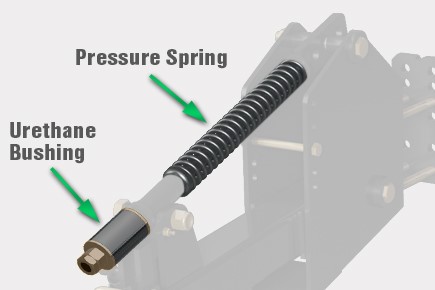

Heavy-duty pressure springs help the tines achieve optimum soil penetration. The arms are also equipment with urethane bushings to absorb shock during transportation. |

|

Choose from 3- or 4-bar harrows for different levels of residue management and field finish. |

|

The mounted harrows can be locked in the “up” position during operation when they’re not required. |

|

Five-head pinwheel nozzles spaced 20 inches apart come standard and are available with 80- or 110-degree combo tips with stainless steel inserts. |

|

A Raven 4400 system offers independent control of the seven boom sections. It automatically adjusts application rates according to the cart speed, which can be detected with the standard GPS sensor or by connecting the unit to the tractor’s performance monitor or GPS receiver. The controller also displays the actual gallons per acre applied, gallons per minute, total volume applied, remaining tank volume, time, total area worked, vehicle speed and distance traveled. |

|

Every Summers field sprayer comes with a 71-gallon side-mounted rinse tank, but this option allows you to add a second. |

|

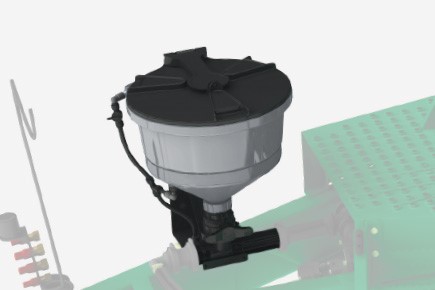

The 5.5-gallon chemical inductor system provides ground level, foam reduced filling of liquid and dry chemicals as well as flowable powders, inducting them directly into the top of the sprayer. |

|

Prevent foreign objects from entering the spray tank with a strainer basket. |

|

You can opt for 22-inch spacing, rather than the standard 20-inch spacing. |

|

Add a 25-gallon foam marker kit to mark your lines. |

|

Start and stop the sprayer anywhere within 100 feet of the control box for easy calibration and maintenance. This means you can turn the nozzles on and off while walking around the booms. |

|

This add-on gives you in-cab pressure readings through the electronic control system. |

|

A joystick provides fingertip controls, so you can alternate circuits without changing hand positions. |

Adjustable Tine Angle

Adjustable Tine Angle Fine-Tune Tine Aggressiveness

Fine-Tune Tine Aggressiveness Adjustable Arm

Adjustable Arm Free-Floating Tines

Free-Floating Tines Crossbar Leveling

Crossbar Leveling The Ideal Match

The Ideal Match Compression Springs/Bushings

Compression Springs/Bushings 3- and 4-Bar Harrows

3- and 4-Bar Harrows Locking Positions

Locking Positions Nozzles

Nozzles Electronic Control System

Electronic Control System Auxiliary Rinse Tank

Auxiliary Rinse Tank Clean Load System

Clean Load System Strainer Basket

Strainer Basket 22-Inch Nozzle Spacing

22-Inch Nozzle Spacing Foam Marker

Foam Marker Electronic Remote Control

Electronic Remote Control Electronic Gauge Package

Electronic Gauge Package Control Grip

Control Grip